For detailed information about the product, you can download the relevant documents.

Automatic Surface Pitching Machines

It is the world’s most serial blasting stone manufacturing machine.

The appearance surfaces of natural stone, marble, travertine, brick, tile, lock stone and other materials gives the appearance of a tree that has been flamed and hammered or cut off in the vertical bark.

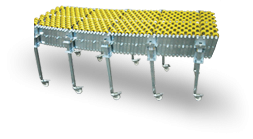

Conveyor belt speed can be adjusted up to 0-3,5m/min.

Processing engine power can reach up to 2.2 kw.

With the machine;

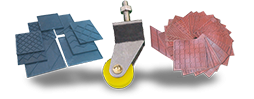

-Tool sets for four different dimensions that customer will use (shown in table)

-Measure adjustment silvers,

-Measure adjustment mountings,

-Measure cutting devices are supplied.

Automatic Liquid Lubrication System

Automatic surface broken machine, cutter head bearings and all working on each other are lubricated with automatic lubrication from the central system.

In the automatic liquid lubrication system, when the liquid oil falls below a certain level, the machine automatically shuts itself off and doesn’t work until the oil chamber is re- filled with supplemental oil.

Serial Production With Yp-200

At the entrance and in the machine, adjustable stone printing systems are available in the automatic surface broken machine. 5, 7.5, 10, 15, 20 cm (optional) surface width Stones are produced by the machine for decorative purposes. In order for the machine to perform mass production, the stone thickness should be at least 1/3 of the surface width (the type of stone, hardness-softness-dry etc.). During the duplicate production phase, natural or artificial Stones are given to the machine and the surface flapping process is taken out of the machine in the finished way. During the broken, the waste is placed under the machine and the machine’s integrated wheelbarrow can be dropped on its own and easy to clean. As a duplicate production target, Toksel Makine Automatic Surface Broken Machines have stone printing systems.