You may download related documents about the product for detailed information.

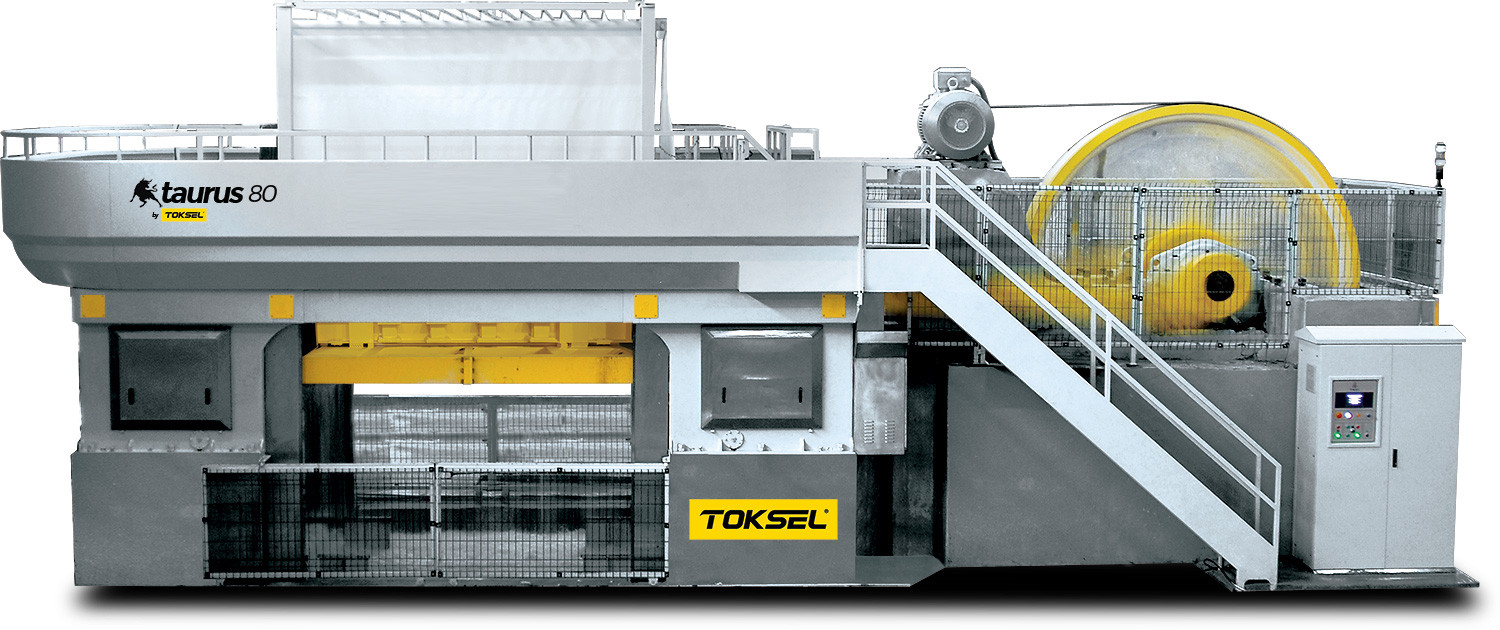

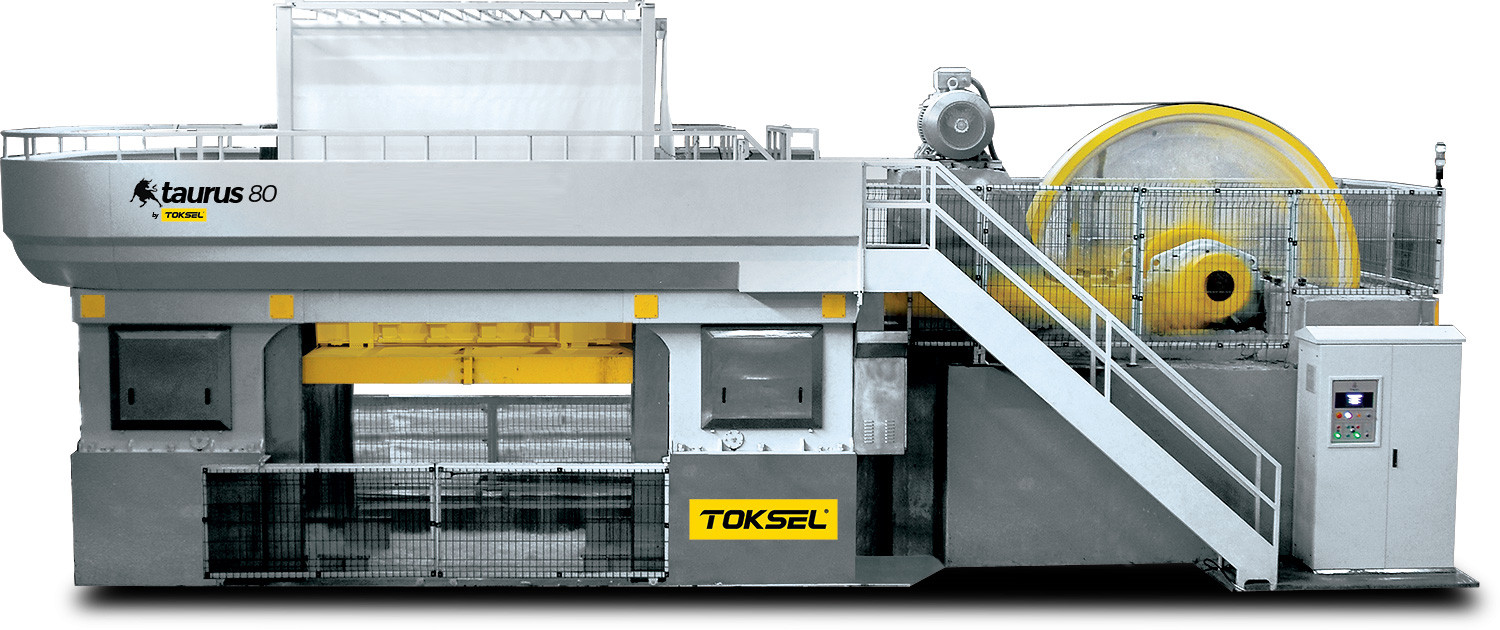

Taurus-80 Gang Saw Machine

Taurus ® offers first class production joy due because it is produced and equipped with finest quality materials. Thanks to silentblock system which requires less energy and offers high performance compared to frictional systems, vibration is minimized and marble, travertine block and rubbles are turned into raw plate block by Taurus ® with the least damage even in cold areas.

Production Under Harsh Conditions

High performance production even in harsh winter conditions is the feature that distinguishes Taurus ® from other machines. In gang-saw machines with hydrostatic system, hydraulic oil in pipes might freeze during winter periods, resulting in burst pipes. This hinders hydrostatic gang-saw machines from working efficiently. Silentblock system used in Taurus ® is the right system in the world.

Monobloc Steel Casting Systems

Silentblocks and connection rods in Taurus ® are designed and produced as monobloc (molded at once) and steel casting. Such systems are vital for Taurus ®. Mechanisms made out of mixture of nodular cast iron and platina sheet metal are strongly discommended because of poor cutting performance.

Flywheel bearings exposed to main engine’s demolishing are manufactured in the quality standarts of monobloc and steel casting.

All the steels present in Taurus ® are manufactured in ST 52 standarts aiming minimum vibration in all over the machine.

IP impermeability technology standarts and occupational health and safety rule over the machine.

Rubble Cutting Module

With ruble cutting module, Taurus ® have justified pride of unique service to its users.

Along with it is the only machine with rubble cutting module Taurus ®’ superior features are listed below;

- The main motor is equipped with a soft starter. The first departure from slow to fast makes controlled departure, emergency stop braking system can do. (In case of emergency, a way to shorten the life of the engine, the engine does not stop with the process of giving the reverse current.)

- The elevator is electronically controlled up and down motor. The taurus ® is designed to be controlled from the water PLC, which is the cutting fluid used during cutting and has an automatic valve system.

- Taurus ® also has an automatic liquid lubrication system. Sliders that help lift up or down are lubricated with automatic liquid lubrication system.

- The block carrier wagon and elevator are interlocked to the linear and horizontal/lateral forces.

- Stone Broken sensors that will stop the flywheel movement during the breakage are found as standard in front and back of Taurus®.